Our products

Biodegradable polymer resins

“Biodegradable plastics: a considerable alternative to recycling.”

It is clear, after use, plastic products should not end up in our streets, rivers, oceans, on landfills and preferably also not as energy source in power plants. It is our task to develop products that can efficiently be re-used or turned into feedstock to form new materials.

In many cases, collection and recycling of plastic products and acquiring the right quality for a new application is difficult, costly or goes with high energy consumption. In these cases, biodegradable plastics can offer a interesting alternative. Also compostable plastics used along with food or other biodegradable products give more uniform waste flows, which stimulates composting or prevents pollution of recycling machines.

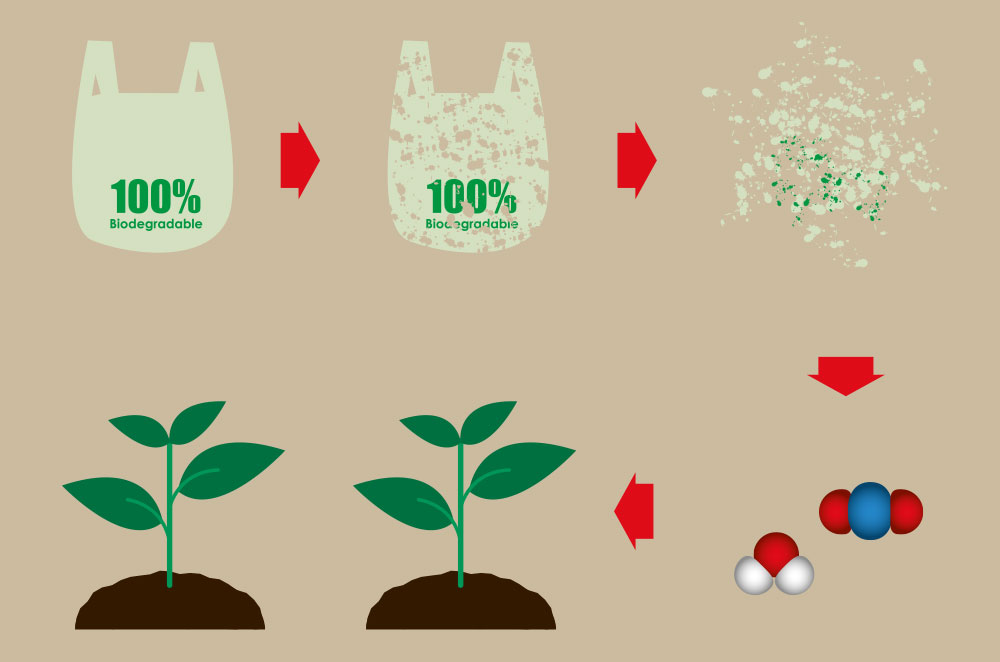

Biodegradable plastics offer excellent, in many cases even durable properties, but their chemical structure allow active bacteria in compost installations to break it down into CO2, water and biomass; building blocks for a new materials.

Our tailor made solutions

A trial with a basic polymer resin may not lead to immediate success. But do not stop there! This is exactly where Pycnoplast offers added value to you. It is in our nature to make it work by turning the resin into a smart compound recipe or develop a masterbatch type of add-on.

“Challenge us with your requirements!”